Polyvinylidene fluoride (PVDF) membrane bioreactors present promising results in treating wastewater. This study focuses on the performance evaluation of PVDF membranes in various system conditions. Key factors such as transmembrane pressure, flux volume, and effluent purity are evaluated to assess the applicability of PVDF membranes for different sewage streams. The outcomes provide valuable information into optimizing PVDF membrane bioreactors for effective wastewater treatment.

Optimization of Operating Parameters in a PVDF MBR System

The performance of a polymeric barrier, particularly polyvinylidene difluoride (PVDF) based membrane bioreactors (MBRs), can be significantly improved by carefully tuning the operating parameters. Key factors that require adjustment include transmembrane pressure, influent flow rate, aeration rate, and temperature. These parameters influence various aspects of the MBR process, such as membrane fouling, microbial growth, and overall efficiency of pollutants.

- Careful selection of transmembrane pressure is crucial to prevent membrane damage while maintaining adequate flux.

- Supply flow rate directly impacts the hydraulic retention time within the MBR, influencing both microbial growth and pollutant degradation.

- Aeration intensity plays a vital role in providing oxygen for microbial metabolism and promoting biomass activity.

- Temperature affects both microbial activity and membrane permeability, requiring careful consideration based on the specific operating conditions.

Membrane Fouling Mitigation Strategies for Enhanced MA BR Efficiency

Membrane fouling remains the primary challenge in maximizing the performance of membrane bioreactor (MBR) systems. To maximize MBR efficiency, mitigating fouling through various methods is crucial. These strategies can be broadly classified into: operational methods to reduce the deposition of foulants onto the membrane surface, and regeneration methods to clear accumulated fouling. Effective implementation of these strategies can significantly enhance MBR performance by minimizing transmembrane pressure, enhancing permeate flux, and optimizing effluent quality.

-

Pre-treatment methods, such as filtration, can successfully eliminate large particles and suspended solids before they reach the membrane, thus reducing initial fouling.

- Operational strategies involve adjusting operational parameters like flow rate to prevent membrane fouling during operation.

- Chemical methods can be employed for biofilm disruption.

These include using dispersants to change the properties of foulants and prevent their adhesion to the membrane.

- Post-treatment methods, such as chemical cleaning, are used to remove accumulated fouling from the membrane surface. These methods can be regularly implemented to maintain optimal membrane performance.

The selection and implementation of appropriate mitigation strategies depend on various factors, including the type of the wastewater, the design of the MBR system, and operational constraints. Ongoing monitoring and evaluation are essential to fine-tune fouling control strategies and ensure long-term MBR efficiency and sustainability.

Advanced Water Purification with Polyvinylidene Fluoride (PVDF) Membranes

Polyvinylidene fluoride sheets, often abbreviated as PVDF, have emerged as a significant material in advanced water purification systems. Their exceptional mechanical resistance, coupled with their ability to form highly efficient membranes, makes them appropriate for removing a broad range of contaminants from water. PVDF membranes can be manufactured through various methods, including electrospinning, resulting in diverse membrane architectures tailored for specific purification applications.

- The water-repellency of PVDF membranes can be adjusted to enhance the removal of both organic and inorganic contaminants.

- Furthermore, PVDF membranes exhibit {highlongevity, allowing for extended service life and reducing maintenance requirements.

- Research into novel PVDF-based membranes are continually exploring innovative approaches to improve water purification efficiency and address emerging water quality challenges.

Membrane Bioreactor Technology: A In-Depth Analysis

Membrane bioreactors (MBRs) represent a sophisticated advancement in wastewater treatment technology. They combine conventional activated sludge processes with membrane filtration to achieve exceptional effluent quality and high solid retention rates. This article provides a comprehensive review of MBR technology, exploring its principles, advantages, applications, and future prospects.

MBRs operate on the principle of separating solids from MBR wastewater using a semi-permeable membrane. This separation process results in highly purified effluent with reduced organic content, nutrients, and suspended solids. The unique characteristics of MBR technology offer several strengths over traditional treatment methods:

* **High Removal Efficiency:** MBRs achieve superior removal rates for pollutants compared to conventional systems.

* **Compact Design:** Their compact footprint makes them suitable for space-constrained areas.

* **Energy Efficiency:** MBRs often demonstrate lower energy consumption than other treatment technologies.

MBR technology has found widespread use in diverse industries and municipalities worldwide, treating a range of wastewater streams. From municipal wastewater to industrial effluents, MBRs provide a reliable and effective solution for achieving stringent effluent discharge standards. The future of MBR technology holds immense promise. Continuous research and development efforts are focused on enhancing their performance, reducing operational costs, and exploring innovative applications.

Applications and Future Prospects of Membrane Bioreactor Systems

Membrane bioreactor (MBR) processes have emerged as a sustainable and efficient solution/approach/method for wastewater treatment. These innovative/advanced/cutting-edge systems combine the benefits/advantages/strengths of both conventional activated sludge processes and membrane filtration, resulting in high-quality effluent/output/discharge. MBRs find wide/broad/extensive applications in various sectors/industries/fields, including municipal wastewater treatment, industrial effluent/wastewater/disposal, and water reuse/reclamation/recycling.

The future prospects of MBR technology are promising/bright/favorable. Ongoing research and development efforts focus on enhancing/improving/optimizing the performance, cost-effectiveness, and sustainability/environmental friendliness/ecological impact of MBR systems. Innovations such as membrane fouling control, energy efficiency enhancements/improvements/optimizations, and integration with renewable energy sources hold great potential/promise/opportunity for advancing MBR technology.

Moreover, the growing global demand for clean water resources is expected to drive/stimulate/accelerate the adoption of MBR systems in developing countries.

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Mason Gamble Then & Now!

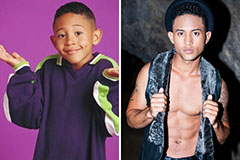

Mason Gamble Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now!